Shared Traceability app for iPhone and iPad

Developer: AHG Incorporated

First release : 17 Sep 2019

App size: 3.52 Mb

Shared traceability is a simple and effective manufacturing traceability / food traceability application.

Using Shared Traceability you can track lot numbers / serial numbers of components, ingredients, intermediate and final products through the process from the origin to the end customer.

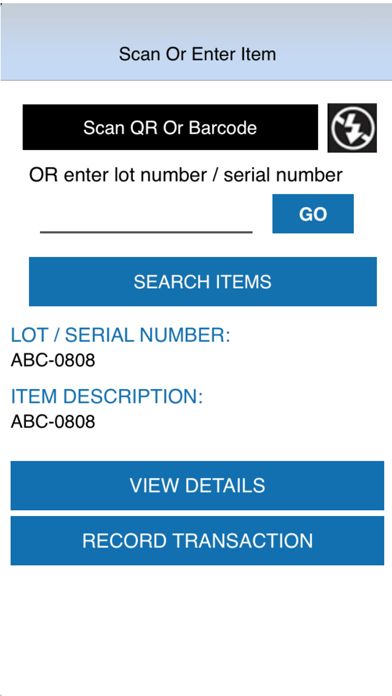

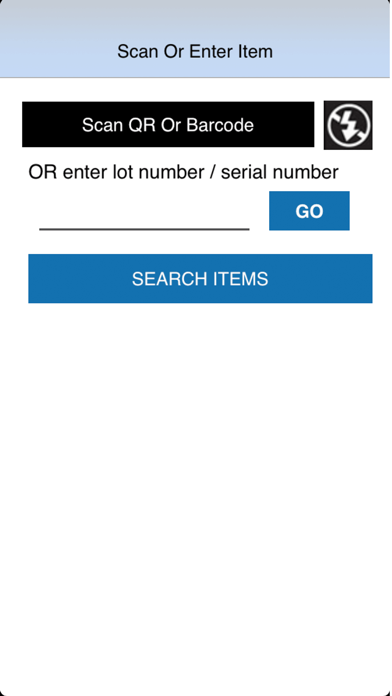

Do all tracking on the shop floor or in the field, using a smartphone for QR code / barcode scanning and recording traceability information. Review the entire traceability history for any component, ingredient or a final product by scanning QR code.

You can use Shared Traceability only within your company, or bring in your supply chain partners for product traceability accross the corporate boundaries.

The main distinctive features of Shared Traceability are:

* Fast to implement - no setup is required, start using right away.

* Flexible - record all data that you need without defining upfront what needs to be recorded.

* Easy to use - Shared Traceability is your next step to a notepad or a spreadsheet.

The difference is that it is much faster and easier to record data with a smartphone, you can use barcode scanning, collect photos and signature, the data are never lost and are always accessible to the authorized users.

* QR code / barcode scanning - use your smartphone to scan in lot numbers / serial numbers of ingredients and final products.

* You can add photos and capture signatures on a smartphone, and add them to the recorded transactions.

* Shared Traceability supports product transformation during the process, such as mixing ingredients together, creating assemblies and kits, splitting a product into several new ones, or converting the product into a different one.

What you can accomplish with Shared Traceability:

* Track components, ingredients and finished products anywhere using barcode scanning. Collect traceability information for each process step as needed.

* Quickly check composition and traceability history of any product. Drill down to find lot numbers of assembly components and their traceability information.

* In case of a problem or recall, quickly find where each lot was distributed, when and all additional details. If the problem is with an ingredient, find all products where this ingredient was used.

* Review process information to find the reason for a problem and correct it.